Product Introduction:

Ultra-narrow powder particle size distribution, improve the flatness of the scraper, high accumulation density, ensure the actual density of the workpiece.

According to the performance of laser sintering, this product is modified first and then graded to ensure the utilization rate of the return powder.

The softening point is close to the melting point, and the range of preheating temperature for the powder in the molding equipment is wide.

Good crystallinity, stable size and small thermal deformation.

Multi-size powder particle size distribution, height from 0.08 to 0.2mm.

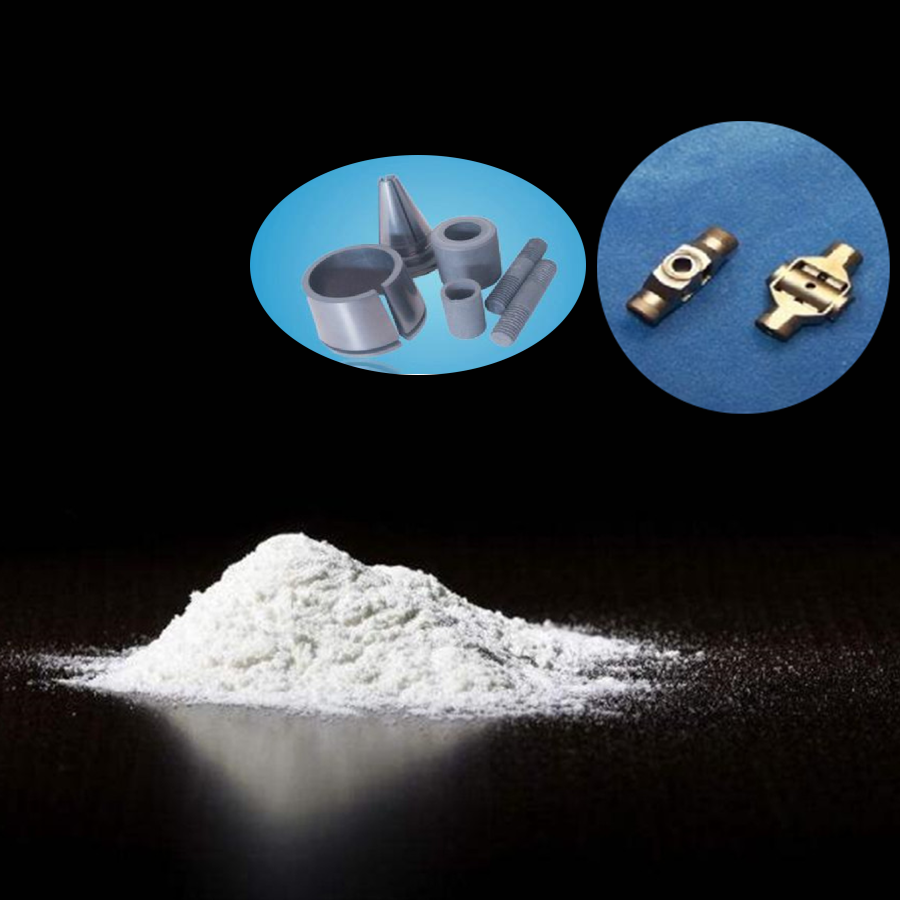

The 3D model is printed by mixing thermoplastic powder and metal powder, and the wax is removed by calcination at high temperature. Obtain the required properties of the metal material structure.

Applicable fields:

Development of 3D printing consumables:

|

|

|

The 3D model is printed by mixing thermoplastic powder and metal powder, and the wax is removed by calcination at high temperature. Obtain the required properties of the metal material structure.

|

Soft and elastic materials are used to print out the athletic soles in a specific shape.

|

Future development of 3D printing:

|

Material performance items

|

Value

|

Units

|

Test standard

|

|

Actual density of material

|

1.37

|

g/cc

|

|

|

Molding shrinkage

|

0.1~0.3

|

%

|

|

|

Loose density

|

0.71

|

g/cc

|

|

|

Particle size Distribution

|

D90

|

52

|

um

|

|

|

|

D50

|

38

|

um

|

|

|

|

D10

|

25

|

um

|

|

|

The density of fabrication

|

1.24

|

g/cc

|

|

|

Melting point

|

230

|

℃

|

|

|

Softening Point

|

200

|

℃

|

Ordinary pressure

|

|

Tensile strength

|

130

|

Mpa

|

ASTM D638

|

|

Elongation at break

|

36

|

%

|

|

Notch impact strength

|

6

|

KJ/m³

|

ISO 179

|

|

Material preheating temperature

|

160~200

|

℃

|

|

|

Molecular weight of material

|

55000~

|

80000

|

|

|

Used for industrial production of high mechanical parts, hand mold, wax mold before casting.

|

Material performance items

|

Value

|

units

|

Test standard

|

|

Actual density of material

|

1.03

|

g/cc

|

|

|

Molding shrinkage

|

0.4~1.0

|

%

|

|

|

Loose density

|

0.51

|

g/cc

|

|

|

Particle size distribution

|

D90

|

72

|

um

|

|

|

|

D50

|

51

|

um

|

|

|

|

D10

|

27

|

um

|

|

|

The density of fabrication

|

0.98

|

g/cc

|

|

|

Melting point

|

172

|

℃

|

|

|

Softening point

|

107

|

℃

|

Ordinary pressure

|

|

Tensile strength

|

49.3

|

Mpa

|

GB/T 1040-2006

|

|

Elongation at break

|

40

|

%

|

|

Notch impact strength

|

3.6

|

KJ/m³

|

GB/T 1043-2006

|

|

Charpy Non-Notch Impact

|

19

|

KJ/ m³

|

|

Material preheating temperature

|

160

|

℃

|

|

Hand mold, ornamental parts, high surface requirements

|

Material performance items

|

Value

|

Units

|

Test standard

|

|

Actual density of material

|

0.95

|

g/cc

|

|

|

molding shrinkage

|

0.4~0.8

|

%

|

|

|

Bulk Density

|

0.47

|

g/cc

|

|

|

particle size distribution

|

D90

|

65

|

um

|

|

|

|

D50

|

55

|

um

|

|

|

|

D10

|

23

|

um

|

|

|

The density of fabrication

|

0.90

|

g/cc

|

|

|

melting point

|

178

|

℃

|

|

|

softening point

|

112

|

℃

|

Ordinary pressure

|

|

tensile strength

|

29.3

|

Mpa

|

GB/T 1040-2006

|

|

elongation at break

|

15

|

%

|

|

notch impact strength

|

3.6

|

KJ/m³

|

GB/T 1043-2006

|

|

Charpy Non-Notch Impact

|

19

|

KJ/ m³

|

|

Material preheating temperature

|

160

|

℃

|

|

3D sand casting

Features:

Ultra-narrow powder particle size distribution, improve the flatness of the scraper, high accumulation density, ensure the actual density of the workpiece.

It has good crystallinity, stable size and small thermal deformation.It is applicable to a wide range of industries.

Leave your suggestion and opinion to the product (Please fill out the information

below.* indicates a required field.)