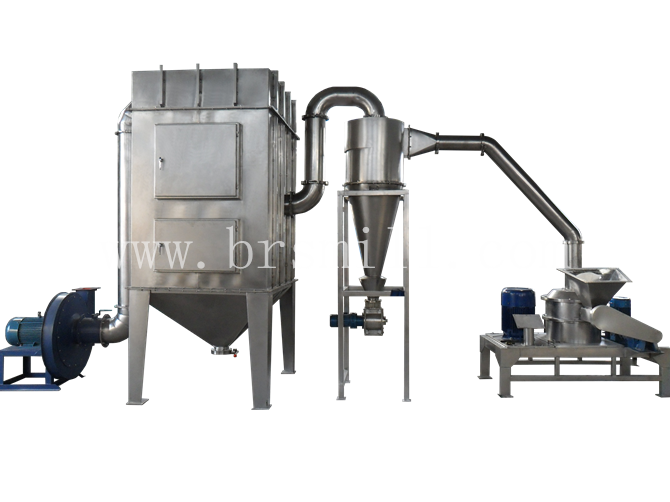

BSP Teff Flour Milling Machine is ACM grindiner (Air classifier mill),

which can make very fine powder. For teff flour milling, the output size can be 70~300mesh.

This mill machine can produce powder very evenly, the distribution of powder is very even.

Working Method:

Raw material is delivered to the grinding chamber via hopper by spiral feeder, and is cut and sheared by the high speed cutters, then the material is moved into the whirlwind separator and the sack dust catcher by the negative pressure sucking method, the ejection material meets the product requirement. That's why it can make super fine powder and can be used as a Fine powder grinder (Fine powder mill)

(1)The left motor is crush motor;the right motor is classifier motor.It adopts a small screw feeder, make sure feed speed is even and controllable.

(2)Material enters the mill chamber via screw conveyor where it is sheared and milled by fast-rotating blades.The powder passes the guide ring and enters the classifier chamber.

(3)Rotary valve make powder discharge speed even,Rotary valve is also made of stainless steel and to clean it and dismantle is convenient.

(4)Dust is collected inside the dust collecting box.

(pic of our Air classifier mill,Air classifing grinder in user's factory )

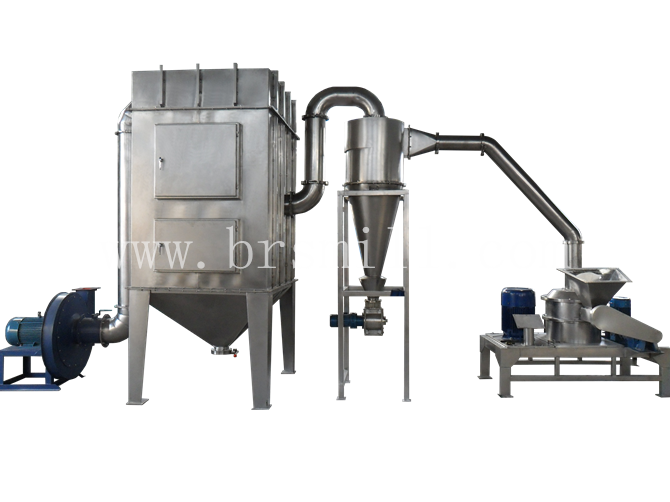

This machine has such specialties:

1.The design is compact and structure is reasonable. The material is equipped with an internal classification mechanism so that grinding and classification are carried out simultaneously, thus reducing energy consupmtion.

2.Equipped with a blower, which dissipates the heat in the machine continuously, the machine is fit for the grinding of thermal sensitive materials.

3.Having a great adaptability and narrow granularity distribution. The granularity of the product is even and fineness may reach 80-320 mesh.

4.Regulate the speed of the classifier or amount of the air without stopping the machine and evenly distributed products of the required granularity will be obtained.

5.The top cover of the main machine is opened with pneumatic springs and the body is constructed in such a way that it may be opened to two sides so that no hindrance will be met in cleaning and servicing the internal parts.

6.The main grinding parts are made of high-grade alloy tool steel so that the service life or change cycle of the wear parts is greatly lengthened.

7.High-speed precision bearings imported from abroad are adopted for the bearing system so that the whole machine runs smoothly with little vibration and noise.

8.The pipes are of quick-detachment construction, making detachment and cleaning quick and convenient.

9.Equipped with a cyclone separator and a collector, so there is no powder flying during production. The dust collecting bag can effectively collect the fine powder in the air current so as to meet the requirements for cleanness and environmental protection in waste gas discharge.

10.The fine powder collected by the dust collecting bag can be effectively recycled. Thus the material loss is reduced.

Leave your suggestion and opinion to the product (Please fill out the information

below.* indicates a required field.)