Introduction to Spice Processing in the Food Industry

- In the food processing industry, spices are not only flavoring agents but also natural preservatives, extending shelf life and reducing the need for artificial additives.

- In the pharmaceutical and nutraceutical sectors, extracts of turmeric, ginger, clove, and pepper are widely used for their bioactive compounds, which support the development of health supplements, herbal medicines, and even functional beverages.

- Spices also play a role in the cosmetic and personal care industry. Essential oils from cinnamon, cardamom, and clove are incorporated into skincare, oral care, and aromatherapy products, providing both fragrance and therapeutic benefits.

- Even in the chemical and fragrance industries, spice derivatives are indispensable. Vanilla, nutmeg, and pepper extracts are processed into natural flavorings and aromas used in perfumes, soaps, and household products.

Raw Material Selection and Preparation

- Raw material selection is a critical step in spice manufacturing, as it affects the quality of the finished product –

- Spice machine manufacturers recommend proper cleaning and washing of raw spices before processing

- Removing impurities and contaminants is essential for producing high-quality spices

- Optical sorters and other equipment are used to sort and clean raw spices

- Minimum order quantity and production capacity are important factors to consider when selecting spice processing equipment

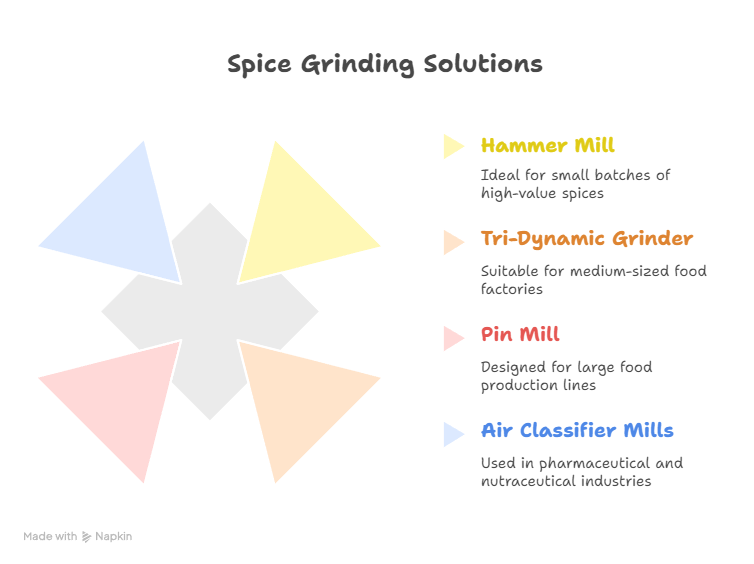

Milling and Grinding Processing

- The milling and grinding process is a critical stage in spice manufacturing, as it affects the flavor and quality of the spices –

- Spice grinding machines use various techniques, including fine grinding and fluidized bed dryers, to produce high-quality spices –

- Hot air and rotary dryers are used to remove moisture from spices and enhance shelf life –

- Bucket elevators and ribbon blenders are used to mix and blend spices –

- The type of grinding machine used depends on the type of spice and the desired finished production processing

https://brsmill.com/crusher-mill/

https://brsmill.com/crusher-mill/

Spice Grinding Machines and Equipment

- Spice grinding machines are designed to grind whole spices into powder form, preserving essential oils and flavor

- Turmeric powder making machine and other spice processing equipment are used to produce high-quality spices

- The spice machine is designed to handle different types of spices, including coriander, cumin, and ginger

- Pepper and salt are also processed using specialized spice grinding machines

- The equipment is made of stainless steel to ensure durability and easy cleaning

Drying and Preservation Techniques

- Drying and preservation techniques are critical in spice manufacturing, as they affect the shelf life and quality of the spices –

- Fluidized bed dryers and rotary dryers are used to remove moisture from spices –

- Hot air and other drying techniques are used to preserve essential oils and flavor –

- The drying process is controlled to prevent damage to the spices –

- The finished product is packaged to preserve freshness and flavor

Moisture Content and Quality Control

- Moisture content is a critical factor in spice manufacturing, as it affects the shelf life and quality of the spices –

- Quality control measures are implemented to ensure that the spices meet the required standards –

- Moisture content is controlled using various techniques, including drying and preservation –

- The spices are tested for quality and purity before packaging –

- The manufacturing process is designed to produce high-quality spices with low moisture content

Production Capacity and Scaling

- Production capacity and scaling are critical factors in spice manufacturing, as they affect the efficiency and profitability of the business

- The manufacturing process is designed to produce high-quality spices in large quantities

- The equipment is designed to handle different production capacities, from small to large

- The business can scale up or down depending on demand

- The equipment is designed to be flexible and adaptable to changing production needs

Maintenance and Repair of Equipment

- Maintenance and repair of equipment are critical in spice manufacturing, as they affect the efficiency and profitability of the business

- The equipment is designed to be durable and easy to maintain

- Regular maintenance is performed to prevent breakdowns and ensure optimal performance

- The equipment is repaired promptly in case of breakdowns

- The business has a maintenance schedule to ensure that the equipment is always in good working condition

Equipment Selection and Manufacturer

- Equipment selection and manufacturer are critical in spice manufacturing, as they affect the quality and efficiency of the business

- The business selects equipment from reputable manufacturers

- The equipment is designed to meet the specific needs of the business

- The manufacturer provides training and support to ensure optimal performance

- The business evaluates the equipment regularly to ensure that it is meeting the required standards