In the world of industrial size reduction, selecting the right milling technology can have a major impact on your product quality, efficiency, and bottom line. Two of the most versatile and widely used systems are the Air Classifier Mill (ACM) and the Wide Chamber Pin Mill. While both are excellent for fine and ultra-fine grinding, they operate on different principles and excel with different material characteristics.

Working Principle:

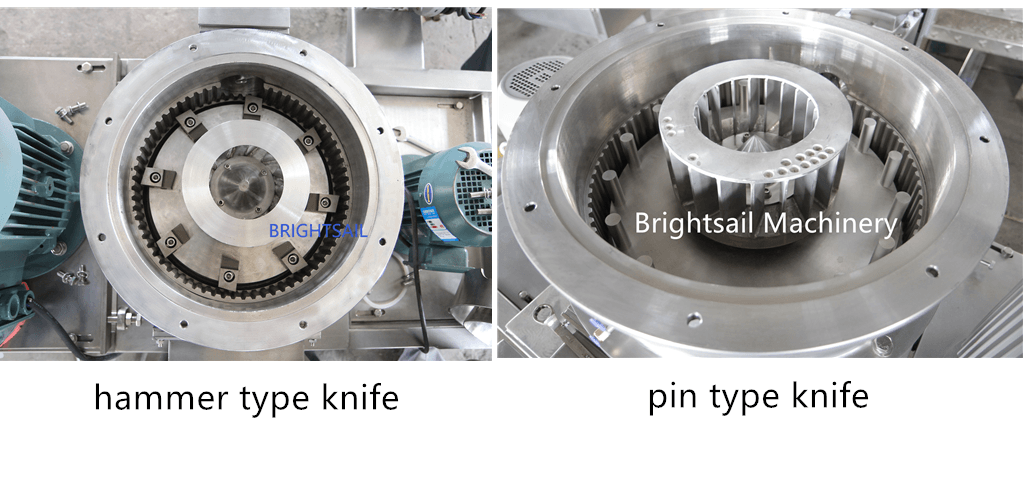

Air Classifying Mill (ACM): The ACM combines an impact mill with an integrated dynamic air classifier. Upon entering the grinding chamber, material is subjected to impact forces by a rotor fitted with hammers or pins. Ground particles are conveyed by airflow to an integrated classification wheel. This wheel functions as a precision classifier: fine particles reaching the classification point (set by rotational speed) enter the dust collection system, while coarse particles are returned to the grinding zone for further reduction. This forms a closed-loop grinding and classification system.

Wide Chamber Pin Mill (WCPM): Pin mills primarily operate through shear forces and impact generated between two discs—a stationary disc (stator) and a rotating disc (rotor). Material entering the chamber centre is accelerated outward by the rotor pins, undergoing repeated collision and shearing between intermeshing pins. The final particle size is determined by the combined effects of pin speed, pin gap, feed rate, and material properties.

Head-to-Head Comparison

| Primary Mechanism | Impact + Integrated Air Classification | Impact & Shear (Pin-to-Pin) |

| Particle Size Range | Tighter distribution, precise top-size control (D97 from 10µm to 150µm typical) | Broader distribution, very fine to coarse possible (D90 from 20µm to several hundred µm) |

| Heat-Sensitive Materials | Excellent. High air flow provides inherent cooling. | Good. The “wide chamber” design allows for longer residence time and some cooling, but less than ACM. |

| Abrasive Materials | Can be challenging. Wear on grinding elements and classifier wheel. | Often superior. Simpler design, no high-precision classifier; pins can be coated (e.g., tungsten carbide) for wear resistance. |

| Fatty/Oily, Sticky Materials | Good, but can face challenges if material melts or gums. High air flow can help. | Excellent. The “wide chamber” resists clogging, and the pin action is often self-cleaning. Ideal for spices, resins, etc. |

| Fibrous Materials | Can be difficult; fibers may wrap on the rotor. | Generally better. The shear action of pins is effective at cutting and tearing fibers. |

| Energy Efficiency | High for achieving specific, fine cuts. No over-grinding due to classifier. | Can be efficient, but may lead to more over-grinding if very specific top cuts are needed. |

| Control & Flexibility | Highly flexible. Fineness adjusted on-the-fly via classifier speed. | Adjusted by changing pin configuration, rotor speed, or feed rate (less dynamic). |

Opt for an Air Classifier Mill (ACM) when requiring the following characteristics:

– Simultaneous grinding and classification within a single unit.

– Heat-sensitive materials such as sugars, pigments, minerals, herbs, chemical powders, or resins.

– Preparation of ultra-fine (micron-grade) powders with narrow particle size distribution.

Typical materials: cocoa shells, titanium dioxide, limestone, carbon powder, thermoplastic powders, fine chemicals.

Opt for a wide chamber pin mill (WCPM) when processing:

– Oily, viscous or greasy materials (e.g. cocoa nibs, spices, coriander seeds).

-Applications prioritising structural simplicity, robust equipment, and ease of cleaning.

-Typical materials: Chilli peppers, black peppercorns, coriander seeds, etc.

Conclusion

There is no universally “best” mill for all applications. Selection depends on the specific physicochemical properties of the material and the required final product specifications.

If precision, classification and cooling performance are paramount considerations, an air-classifying mill is likely to be the preferred choice.

When confronted with the challenges of abrasive, viscous or fibrous materials, a robust, shear-focused wide-chamber needle mill may prove the more suitable alternative.