Introduction to Fine Grinding

- The air classifying mill market is driven by increasing demand for ultra-fine powders in various industries, including food, pharmaceuticals, and chemical processing.

- Air classifying mills offer precise control over particle size distribution, ensuring narrow particle size distributions and high-quality products.

- The internal air classifier plays a critical role in achieving precise particle size control and efficient processing.

- The Rise of Air Classifier Mills: Replacing Legacy Grinding Systems

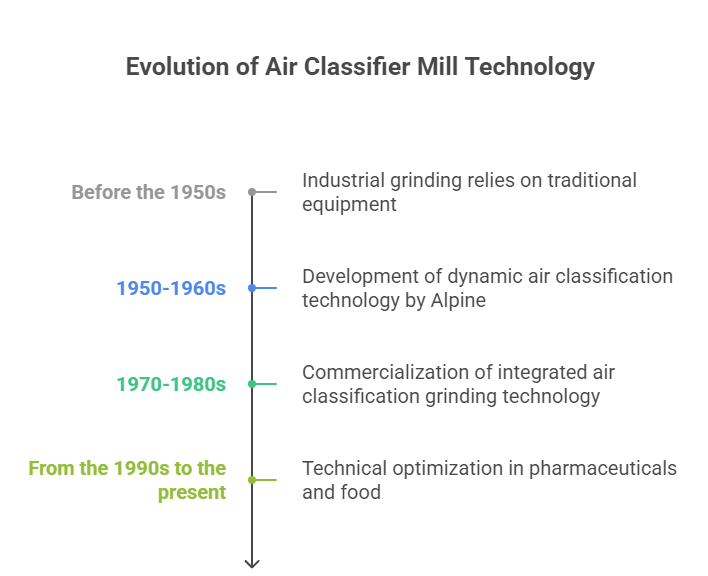

- Before the 1950s, industries relied on hammer mills or ball mills with external classifiers to achieve fine powders. These systems faced critical limitations: sieve blinding (especially for sticky materials), high energy waste from over-grinding, and inconsistent particle distribution.

- The breakthrough came with integrated air classifier mills in the mid-20th century. By embedding a high-speed classifier wheel directly into the grinding chamber, these mills could:

- Instantly separate fine particles via aerodynamic forces (instead of physical sieves),

- Adjust particle size on-the-fly by simply changing the wheel’s RPM,

- Cut energy use by 30-50% by eliminating recirculation.

- Manufacturers like Alpine pioneered this technology in the 1960s, and by the 1980s, it became the gold standard for mineral processing. Today, advanced mills (e.g., BRIGHTSAIL’s custom designs) further push the limits in pharmaceuticals and food, where precision and hygiene are non-negotiable.

Principles of Operation

- The air classifying mill operates on the principle of size reduction, using a combination of grinding and air classification to produce ultra-fine powders.

- The grinding zone is designed to optimize particle size reduction, with the internal air classifier ensuring that only on-size particles pass through to the next stage.

- The classifier mill technology is based on the principle of air flow and classifier speed, which can be adjusted to achieve the desired particle size distribution.

- The air classifier mill is capable of handling heat-sensitive materials and can be used in a broad range of industries, including powder coatings, pharmaceuticals, and food processing.

- However, air classifier mills aren’t suited for everything. Sticky substances like powders derived from materials with high oil or sugar content will adhere to the classifier wheels. This inherent issue is a key reason behind the wide array of grinding technologies available.

Principles of Operation

The air classifying mill operates on the principle of size reduction, using a combination of grinding and air classification to produce ultra-fine powders.

The grinding zone is designed to optimize particle size reduction, with the internal air classifier ensuring that only on-size particles pass through to the next stage.

The classifier mill technology is based on the principle of air flow and classifier speed, which can be adjusted to achieve the desired particle size distribution.

The air classifier mill is capable of handling heat-sensitive materials and can be used in a broad range of industries, including powder coatings, pharmaceuticals, and food processing.

Sticky Materials & Your Classifier Mill: Why Expertise Matters

Beware: Classifier wheels in superfine mills are notoriously vulnerable to sticky substances. Powders high in oils, sugars, or binders can rapidly adhere to rotating blades, causing:

Flow disruption & uneven particle distribution

Buildup-induced imbalance leading to vibration/shutdown

Cross-contamination between batches

This isn’t a minor nuisance – it’s a critical failure risk that escalates maintenance costs and cripples productivity.

Protect your investment with 3 proactive steps:

Demand material-specific consultations with manufacturers before purchasing. Generic specs won’t suffice.

Insist on grinding trials using your actual feedstock. Observe how the mill handles viscosity at target fineness (e.g., D97 < 40μm).

Verify anti-adhesion engineering – look for:

Specialized rotor coatings (e.g., nano-ceramic, PTFE)

Mechanical scrapers or air-knife cleaning systems

Temperature control to harden sticky components

The bottom line: Sticky materials demand mill customization. Partner with technical specialists like BRIGHTSAIL who engineer solutions, not just sell machines. Skip this due diligence, and your “high-efficiency” mill may become a $20k paperweight.

Classifier Mill Technology

- The classifier mill technology is designed to provide precise control over particle size distribution, with the ability to produce narrow particle size distributions and ultra-fine powders.

- The internal air classifier is a key component of the classifier mill, allowing for precise control over particle size and distribution.

- The classifier wheel is designed to optimize particle size classification, with the ability to adjust the classifier speed and air flow to achieve the desired results.

- If you’re having trouble visualizing the classifier wheel in a superfine mill, think of it like this: Imagine a high-speed fan spinning inside the grinding chamber. This fan acts as a barrier, preventing the powder from freely escaping.

Here’s the key: When the fan spins very fast, only the tiniest particles can slip through the powerful airflow it creates.Slow the fan down, and slightly larger particles gain enough momentum to pass through as well.Traditional hammer mills force operators into a time-consuming screen swap dance:Need finer powder? → Replace the screenCoarser product required? → Replace the screen againThis mechanical bottleneck halts production and inflates operational costs.Superfine air classifier mills revolutionize this process:Simply adjust the classifier wheel’s RPM → Instant precision control from D97=20μm to 70μmZero physical part changes – achieve target fineness in seconds via control panel

Here’s the key: When the fan spins very fast, only the tiniest particles can slip through the powerful airflow it creates.Slow the fan down, and slightly larger particles gain enough momentum to pass through as well.Traditional hammer mills force operators into a time-consuming screen swap dance:Need finer powder? → Replace the screenCoarser product required? → Replace the screen againThis mechanical bottleneck halts production and inflates operational costs.Superfine air classifier mills revolutionize this process:Simply adjust the classifier wheel’s RPM → Instant precision control from D97=20μm to 70μmZero physical part changes – achieve target fineness in seconds via control panel - Legacy grinding solutions like hammer mills chain operators to physical screens. Every particle size adjustment demands wrench time, production pauses, and spare parts inventory. Modern superfine mills break this tyranny. By manipulating the classifier wheel’s rotational speed – not mechanical components – operators now command precise fineness shifts at the touch of a button. This agility is transforming powder processing from batch-driven to demand-driven operations.“Switching from 40 mesh to 80 mesh powder used to take our team 25 minutes of downtime. With BRIGHTSAIL‘s ACM, we now dial it in remotely before coffee cools.”— Production Manager, Chemical Powder Plant

- The stationary liner is designed to minimize wear and tear, ensuring easy maintenance and reducing downtime.Furthermore, the blade design within an air classifier mill isn’t fixed or one-size-fits-all. Different configurations exist, such as cylindrical blades or hammer/impact heads. Reputable manufacturers like BRIGHTSAIL understand this and excel at selecting or even custom-designing the optimal blade geometry based on a client’s specific material characteristics and processing requirements.

Blade Geometry Matters: Choosing the Right Tool for Your Powder:

In superfine air classifier mills, two blade profiles dominate particle engineering:

Rectangular Hammer Blades – The tough workhorses for abrasive warriors:

→ Ideal for: herbs, grains, minerals, hard materials

→ Edge retention: 3X longer than pins in high-wear tests

→ Trade-off: Higher energy consumption per ton

Cylindrical Pin Blades – The gentle giants for crystalline fragility:

→ Master of: Sugar, salt, pharmaceutical crystals

→ Secret weapon: 20-30% higher airflow throughput

→ Bonus: Creates turbulent vortices → +15% capacity vs. hammers

“Switching from hammers to pin blades cut our sucrose grinding energy by 18% and boosted yield to 2.1 ton/hr. The crystal fracture perfection was a game-changer.”

— BRIGHTSAIL FoodTech Customer Case

“Stop forcing square blades into round challenges. Pin blades dominate sugary, heat-sensitive, and low-melting-point applications not just through geometry – their secret lies in aerodynamic efficiency. For cocoa butter or ascorbic acid? This is non-negotiable.”

Dual-Rotor Strategy:

The Smart Path to Versatile Grinding

Savvy powder processors don’t compromise – they deploy two specialized rotor assemblies, each armed with purpose-built blades:

Energy Savings:

Pin blades cut sugar grinding power by 18% vs. hammers

Dedicated rotors eliminate “compromise settings” wasting 9-14% energy

Zero Downtime Profit:

Switch configurations in <2 hours (vs. 8+ hrs cleaning/re-tooling single rotor)

Save $1,600/shift in lost production

“Running icing sugar and cinnamon on separate BRIGHTSAIL rotors cut our energy bill by $12k/year. The hammer rotor grinds cinnamon at 350kg/h (75μm), while the pin blade rotor handles icing sugar at 900 kg/h – impossible with a single setup.”

— Spice Processor ROI Report

The Smart Buyer’s Mantra: Expertise Before Investment

While air classifier mills deliver revolutionary particle control, never forget: this is precision industrial artillery – not plug-and-play appliances. The difference between a profit engine and a $20k mistake lies in one non-negotiable step: collaborating with specialized OEMs pre-purchase.

Why this saves your operation:

Material-DNA Decoding: Sugar content? Oil affinity? Explosive potential? Real engineers diagnose these before quoting.

No-Compromise Configuration: From rotor blade geometry (hammers vs. pins) to classifier wheel torque curves – each choice cascades into your kWh/ton.

Future-Proofing: Pharma planning GMP audits? Food eyeing HACCP? Proactive design beats costly retrofits.